Firearms CNC Machining: Precision in Every Shot

In the realm of firearms machining, the choice of materials is paramount. Swiss Machining Inc. delves into the intricacies of metals and alloys, considering their properties and suitability for specific components. Specializing in the production of various firearm elements, such as barrels and receivers, the company emphasizes sustainable practices, ensuring responsible sourcing of materials and implementing recycling initiatives.

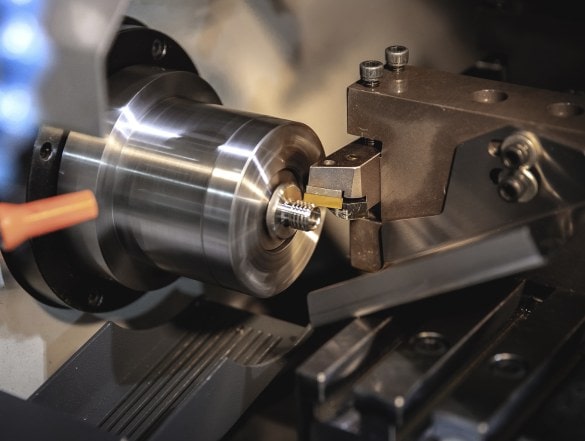

Swiss Machining Inc.'s process unfolds seamlessly from design conceptualization to assembly. The journey begins with meticulous design and prototyping, where ideas take shape and are refined into tangible prototypes. The machining process, executed with precision machinery, is complemented by thorough finishing touches, culminating in the assembly of top-tier firearm components.

Quality control is the bedrock of Swiss Machining Inc.'s operations. Stringent measures, encompassing various tests and inspections, guarantee that each product meets or surpasses industry standards. The company adheres rigorously to established regulations, ensuring that their manufacturing processes align with the highest industry benchmarks. Case studies serve as testaments to their unwavering commitment to quality.

In a rapidly evolving technological landscape, Swiss Machining Inc. remains at the forefront of innovation in CNC machining for firearms. Significant investments in research and development underscore the company's dedication to pushing boundaries and exploring new frontiers. Speculating on the future, the document offers insights into emerging technologies that could shape the future of the industry.

Safety is paramount in Swiss Machining Inc.'s operations, with stringent protocols in place to ensure the well-being of employees throughout the production process. Environmental considerations are not neglected, as the company actively seeks ways to minimize its ecological footprint. Robust employee safety training programs further fortify the commitment to a secure and sustainable working environment.

Swiss Machining Inc. extends a comprehensive range of client services, from initial consultation to the production of customized solutions. Catering to specific client needs, the company prides itself on flexibility and adaptability. Beyond production, Swiss Machining Inc. offers robust after-sales support, ensuring the longevity and optimal performance of their products.